Our Services

Our expertise lies in providing top-notch industrial concrete flooring solutions, meticulously crafted with power trowel finish techniques. With years of experience in the field, we specialize in delivering durable and high-quality concrete surfaces tailored to meet the demands of various industrial settings, including warehouses, factories, and distribution centers. Utilizing advanced power trowel equipment, we ensure that each concrete surface receives a smooth, level finish that not only enhances its aesthetic appeal but also maximizes its functionality and longevity. Our team is dedicated to selecting the optimal concrete mixtures and reinforcement materials for every project, ensuring superior strength and abrasion resistance

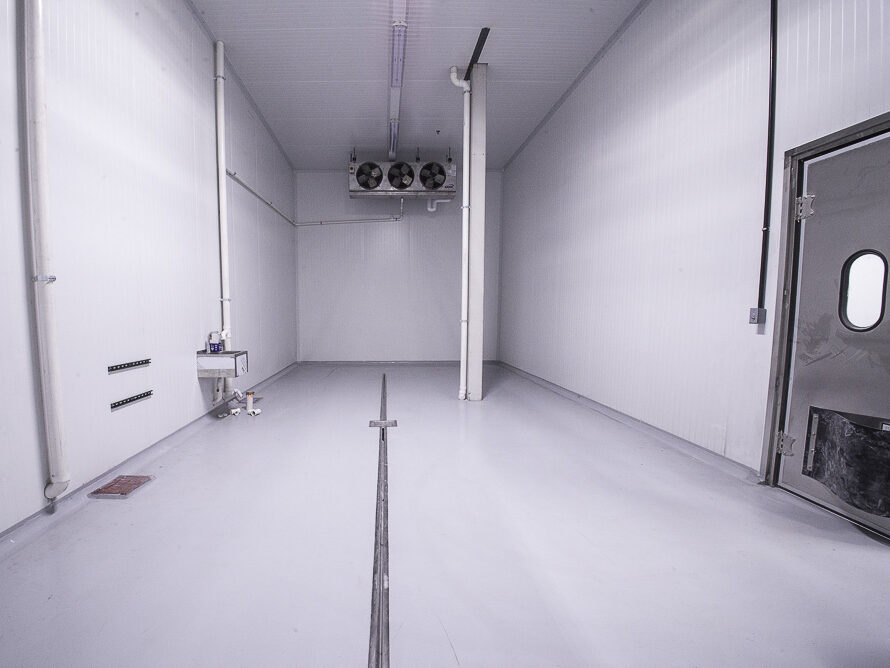

Cold Storage Flooring

When it comes to cold storage flooring, our team specializes in providing robust solutions tailored to withstand the unique challenges of low-temperature environments. With a keen understanding of the requirements for preserving perishable goods, we offer expert guidance and construction services to ensure the longevity and efficiency of your cold storage facilities. Our approach involves selecting high-quality materials and employing specialized techniques to create durable flooring systems that can withstand extreme temperatures and heavy loads. Whether it’s a freezer, refrigerated warehouse, or cold room, our solutions are designed to maintain structural integrity while minimizing the risk of damage from frost, condensation, and thermal expansion.

PU injection, or polyurethane injection, is a highly effective technique used in construction and civil engineering for repairing and strengthening concrete structures. This process involves injecting a specialized polyurethane resin into cracks, voids, or cavities within concrete to fill and seal them. PU injection is commonly used to restore the structural integrity of buildings, bridges, dams, tunnels, and other infrastructure elements affected by cracking, water leakage, or soil erosion.

The process begins with a thorough assessment of the damaged area to determine the extent and cause of the problem. Once identified, small holes are drilled into the concrete at strategic locations to access the affected areas. A polyurethane resin, typically in liquid form, is then injected under pressure into the voids or cracks. As the resin expands and cures, it fills the space, bonds with the surrounding concrete, and forms a watertight seal.

Waterproofing

Waterproofing is an indispensable aspect of construction and building maintenance, pivotal for safeguarding structures against the detrimental effects of water infiltration and moisture accumulation. It encompasses a range of methods and materials aimed at creating barriers to prevent water from penetrating surfaces such as roofs, walls, basements, and foundations. Whether through surface applications like bituminous coatings and elastomeric membranes, integration into concrete mixes for integral reinforcement, or specialized techniques for basement, roof, or foundation waterproofing, each approach serves the common goal of fortifying structures against water-related damage. By implementing effective waterproofing measures, buildings can maintain their structural integrity, extend their lifespan, and ensure a healthier and more comfortable indoor environment. Collaboration with waterproofing experts is essential to select and implement the most appropriate solutions tailored to the specific requirements and conditions of each project.

Comfort Flooring

Comfort flooring is designed to prioritize the well-being and comfort of occupants by providing a soft and supportive surface underfoot. Whether it’s in residential, commercial, or industrial settings, comfort flooring aims to reduce fatigue, strain, and discomfort, particularly in areas where individuals spend extended periods standing or walking. This type of flooring often utilizes materials like rubber, carpeting, cork, vinyl, or foam, each offering unique properties such as cushioning, shock absorption, and resilience. From the warmth and insulation of carpeting to the natural springiness of cork and the durability of rubber, comfort flooring options cater to various preferences and requirements. Beyond physical comfort, these flooring solutions also contribute to improved ergonomics, reducing the risk of muscle strain and joint pain associated with prolonged standing. Whether in homes, offices, retail spaces, or healthcare facilities, comfort flooring creates environments that promote well-being, productivity, and overall satisfaction.

Epoxy Flooring

Epoxy flooring offers a versatile and durable solution for a wide range of residential, commercial, and industrial applications. Composed of epoxy resin and hardening agents, this flooring system creates a seamless, high-gloss surface that is exceptionally resilient to wear and tear, chemicals, stains, and moisture. Whether applied to concrete floors in garages, warehouses, hospitals, or even homes, epoxy flooring provides a smooth and easy-to-clean surface that enhances aesthetics while offering long-term protection.One of the key benefits of epoxy flooring is its exceptional durability and resistance to various forms of damage. It withstands heavy foot traffic, impacts from dropped objects, and abrasion from vehicles and machinery, making it ideal for high-traffic areas and industrial settings.

Grouting

Grouting is a crucial process in construction and renovation projects that involves filling the gaps between tiles, stones, or bricks to create a seamless and aesthetically pleasing surface. This technique not only enhances the appearance of the finished structure but also helps to reinforce and stabilize the installation by preventing moisture penetration and minimizing movement.Grout is typically a mixture of cement, sand, and water, although there are also epoxy-based grouts available that offer increased durability and resistance to staining and cracking. The grout is applied into the joints between tiles or other building materials using a grout float or trowel, ensuring that the gaps are completely filled and the surface is leveled.

Sealants

Sealants are indispensable in construction and maintenance, forming barriers that safeguard building structures from water, air, and contaminants infiltration. These versatile materials are applied to joints, seams, and gaps in various building materials, enhancing durability, energy efficiency, and overall structural integrity. With a range of sealant types available, each tailored for specific applications and environments, including silicone, polyurethane, acrylic, butyl, and asphalt sealants, the selection process considers factors like substrate type, joint width, and exposure conditions. Whether sealing expansion joints, cracks in concrete, or gaps in exterior building envelopes, sealants offer crucial protection against moisture, weathering, and degradation. Proper selection and application of sealants, coupled with regular maintenance, ensure effective sealing and long-term performance, contributing to the longevity and efficiency of building structures.